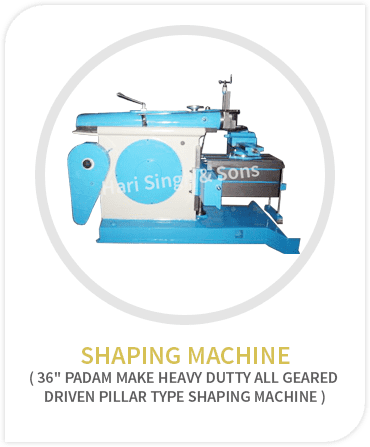

All geared Shaping Machine

Standard Accessories Of Shaping Machine

01.

Swiveling vice.

A vice is a commonly used accessory in shaping machines. It provides a secure and stable clamping mechanism to hold the workpiece in place during shaping operations. The vice typically has adjustable jaws to accommodate different workpiece sizes and shapes.

02.

Automatic oil lubrication pump.

An automatic oil lubrication pump is a critical accessory for a shaping machine. It ensures smooth and efficient operation by providing a continuous supply of lubricating oil to the moving parts of the machine. This helps reduce friction, wear, and heat generation, thereby extending the machine’s lifespan and improving its performance.

03.

Motor pulley

The motor pulley is a key component of a shaping machine that connects the motor to the machine’s drive system. It is typically a wheel-shaped device with a groove or series of grooves on its outer circumference. The motor pulley is usually made of durable materials such as cast iron or steel.

04.

Instruction and maintenance manual

Standard shaping machines come with electrical controls that allow operators to start, stop, and control the shaping operation. These controls may include switches, buttons, and indicators for safety and ease of use.

Harisingh and Sons proudly presents the “All Geared Shaping Machine,” a cutting-edge industrial tool designed to revolutionize shaping processes. This state-of-the-art machine combines precision engineering with advanced features to deliver unparalleled performance and efficiency.

Hari Singh and Sons provide highly efficient Shaper Machines that is immensely used in various technical and engineering sectors. The company’s aim is now to be the largest Shaping machine manufacturer in India. Its salient features are compact construction, high speed, and the long life of the machine. Our shaping machine manufacturer in Ludhiana deals with high-grade raw materials satisfying all the quality standards like C.I. casting according to IS: 210 which ensures the long life of the machine and all alignments according to IS: 2310 – 1989. Being a user-friendly machine, it can be very easily operated and handled. The machine is low in maintenance and high in performance.

- Heavily Cross ribbed robust and sturdy construction to ensure vibration free working.

- Specially designed for increase production, precision, performance and deep cut.

- Fully hand scrapped.

- Double jack system (no more digging of pits).

- Clutch within easy reach of operator.

- Selected special alloy steel used for screws, shafts and steel parts.

- Expanding ring type clutch drive in all geared machines to eliminate slippage.

- Graduated Total Slide swiveling 90 degrees either way.

- Padam Shapers for a deep cut-high metal removal and sustained accuracy.

- Accuracy plus simplicity is the compact nature of our SHAPING MACHINES

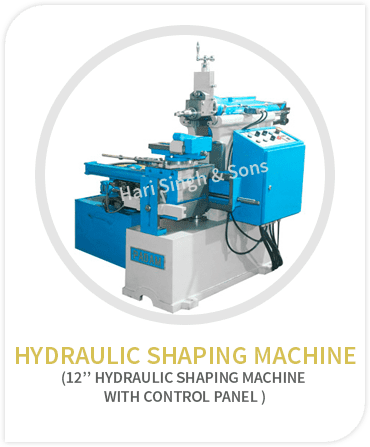

- Electric motor

- Dol starter

- Keyway cutting attachment

- Automatic tool lilting device

- Automatic feed to the tool slide

- Rapid feed system with the control panel.

- Allen key set. v-belts, crank handle, spanner set, screwdriver oil can. toolbox.