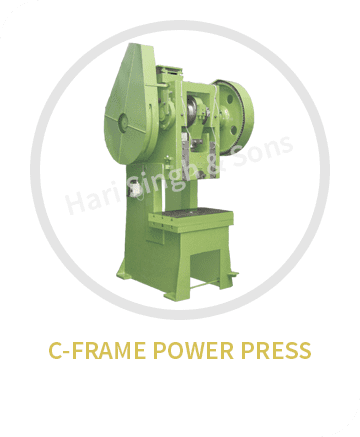

C-frame Power press Machine

Uses of Power Press Machine

01.

Power Press Machine is majorly used in manufacturing industries for getting the casing ready for the appliances

02.

Due to its multi-functionality feature, it is used in all the factories and industrial establishments.

03.

Power pressing machine is one of the most important machines to learn for every engineering student, so is the part of every technical institute’s workshop

04.

This machine is part of every electronic and electric appliance factory.

The C Frame Power Press Machine boasts exceptional versatility and adaptability, thanks to its adjustable stroke length, variable speed control, and customizable tooling options. This enables operators to tailor the machine to specific requirements and optimize productivity.

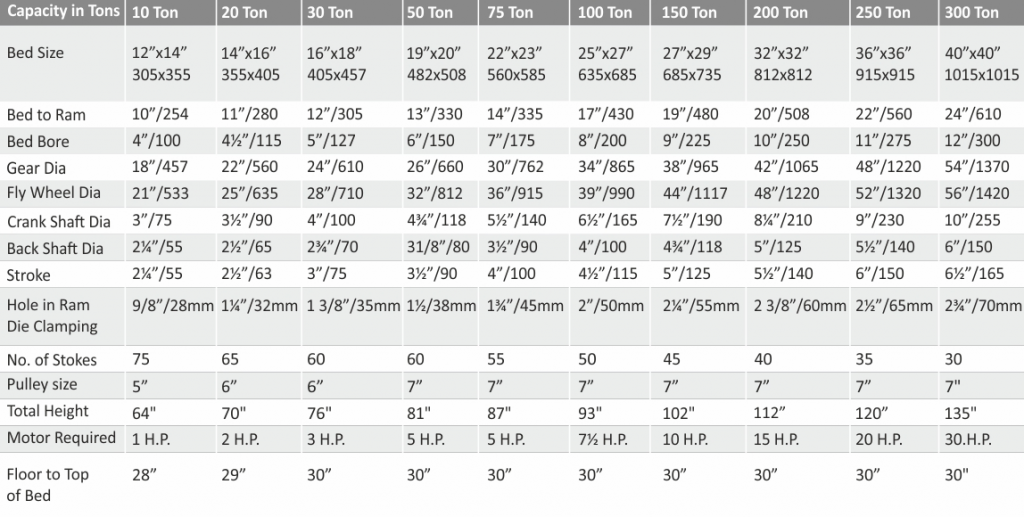

As the name suggests, the shape of the machine is like the letter ‘C’. The main parts of the machines are Gears, crankshaft, clutch, ram, and table. This C frame power press has a capacity of 3 tons to 250 tons

A C frame power press is a type of mechanical press commonly used in industrial applications for various metalworking operations. It is named after its distinctive C-shaped frame structure.Mechanical C Type Press Machine fabricated from IS-2062 graded rolled steel plates. The frame is deeply reinforced and fines machines after stress relieving. The interlocked design put direct support to the frame. This frame is strain free and eliminates welds at load supports. Thus the accuracy of the machine is never disturbed.

Hydraulic Power System: Hydraulic shaping machines utilize a hydraulic power system that generates and controls the hydraulic pressure required for shaping operations. It consists of hydraulic pumps, valves, cylinders, and other components.

Pressure and Force: Hydraulic shaping machines provide high pressure and force, allowing for efficient shaping of various materials. The hydraulic system delivers substantial force to the shaping tools, enabling precise and controlled shaping processes.

Adjustable Speed and Pressure: These machines offer adjustable speed and pressure control, allowing operators to optimize the shaping process based on the material, desired shape, and other factors. This flexibility ensures accurate and consistent shaping results.

Shaping Tools and Dies: Hydraulic shaping machines are compatible with a range of shaping tools and dies. These tools can include punches, dies, molds, and other specialized shaping equipment. The machine’s design allows for quick and easy tool changes to accommodate different shaping requirements.

Multiple Shaping Techniques: Hydraulic shaping machines support various shaping techniques, such as shearing, bending, drawing, extrusion, flanging, and more. They offer versatility in terms of the types of shapes and forms that can be achieved.