Cone Pulley Drive Shaping Machine

Standard Accessories Of Shaping Machine

01.

Swiveling vice.

A vice is a commonly used accessory in shaping machines. It provides a secure and stable clamping mechanism to hold the workpiece in place during shaping operations. The vice typically has adjustable jaws to accommodate different workpiece sizes and shapes.

02.

Automatic oil lubrication pump.

An automatic oil lubrication pump is a critical accessory for a shaping machine. It ensures smooth and efficient operation by providing a continuous supply of lubricating oil to the moving parts of the machine. This helps reduce friction, wear, and heat generation, thereby extending the machine’s lifespan and improving its performance.

03.

Motor pulley

The motor pulley is a key component of a shaping machine that connects the motor to the machine’s drive system. It is typically a wheel-shaped device with a groove or series of grooves on its outer circumference. The motor pulley is usually made of durable materials such as cast iron or steel.

04.

Instruction and maintenance manual

Standard shaping machines come with electrical controls that allow operators to start, stop, and control the shaping operation. These controls may include switches, buttons, and indicators for safety and ease of use.

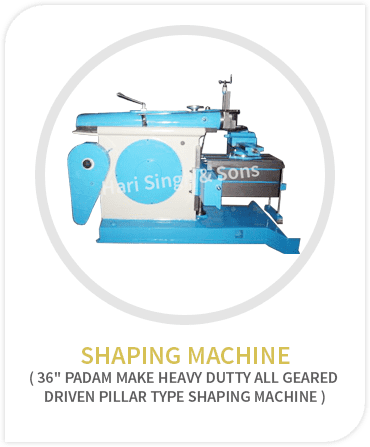

“Harisingh and Sons’ Cone Pulley Drive Shaping Machine offers precision and versatility for shaping operations in the manufacturing industry

They are the leading manufacturer and exporter of high-quality shaping machine manufacturers in India that offer the best performance in any condition. Cone Pulley Drive Shaping Machine, offered by us, are capable of performing as per industrial standards including The close-grained, C. I casting conforming to IS: 210, which ensures the long life of the machine and all alignments confirm IS 2310 – 1989. This makes the company one of the best Shaping machine manufacturers in Ludhiana. The company ensures durability and flawlessness in the performance of the machine making it suitable for all engineering purposes, for both ferrous and non-ferrous materials

- Duly seasoned alloyed high duly castings

- Sturdy construction to ensure vibration-free working

- Ram alignment with taper lib strip

- Extensive lubrication arrangements

- Alloy steels shafts

- Double jack system (no more digging of pits).

- All alignments maintained as pet geometric alignment test is : 2310-1989

- Universal/fixed table with variable

- Automatic feeds on horizontal traverse.

- Graduated tool slide swiveling 90 degrees either way

- Interchangeability of parts

- Ensured through standardization and quality control

- Accuracy and performance guaranteed.

- Electric motor

- Dol starter

- Keyway cutting attachment

- Automatic tool lilting device

- Automatic feed to the tool slide

- Rapid feed system with control panel,

- Allen key set. v-belts, crank handle, spanner set, screw driver oil can. tool box.