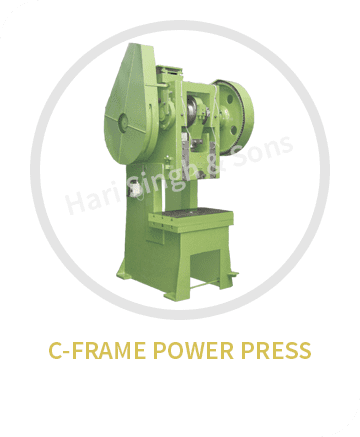

Pneumatic Clutch Power press Machines

What is Pneumatic Power press

Press machines are utilized in set industrial settings for a large range of uses, including squeezing, forming, and pressing. In a pneumatic framework, compressed air is utilized to send and control powers. In today’s industries, different works are finished by utilizing pneumatic frameworks. Like programmed creation lines, mechanical cinches, controlling train doors, and so on.There are various types of presses. Pneumatic presses are maintained by the pressurized air. The air is slave into a tube that fills with the air and applies pressure that causes the press to move downwards. Once the press’ stroke is finished, the air is evacuated through valves and mechanical spring elements. The pump moves upwards again.

The pneumatic press’s greatest advantage is its speed. They can change ten times faster than hydraulic presses. They can also stop at any time that the operator opens the tap to release the air.Pneumatic power presses are quite versatile, able to be placed in a factory in any position in which the operator requires it to be, even upside down. Pneumatic presses are easy to use, and the controls resemble those of more traditional styles of the press.

Uses of Power Press Machine

01.

Power Press Machine is majorly used in manufacturing industries for getting the casing ready for the appliances

02.

Due to its multi-functionality feature, it is used in all the factories and industrial establishments.

03.

Power pressing machine is one of the most important machines to learn for every engineering student, so is the part of every technical institute’s workshop

04.

This machine is part of every electronic and electric appliance factory.

Done FAQ For you

What is Pneumatic Power press Machine?

What are Pneumatic Press Safety Procedures?

Properly release compressed air, Restrain all equipment tubing